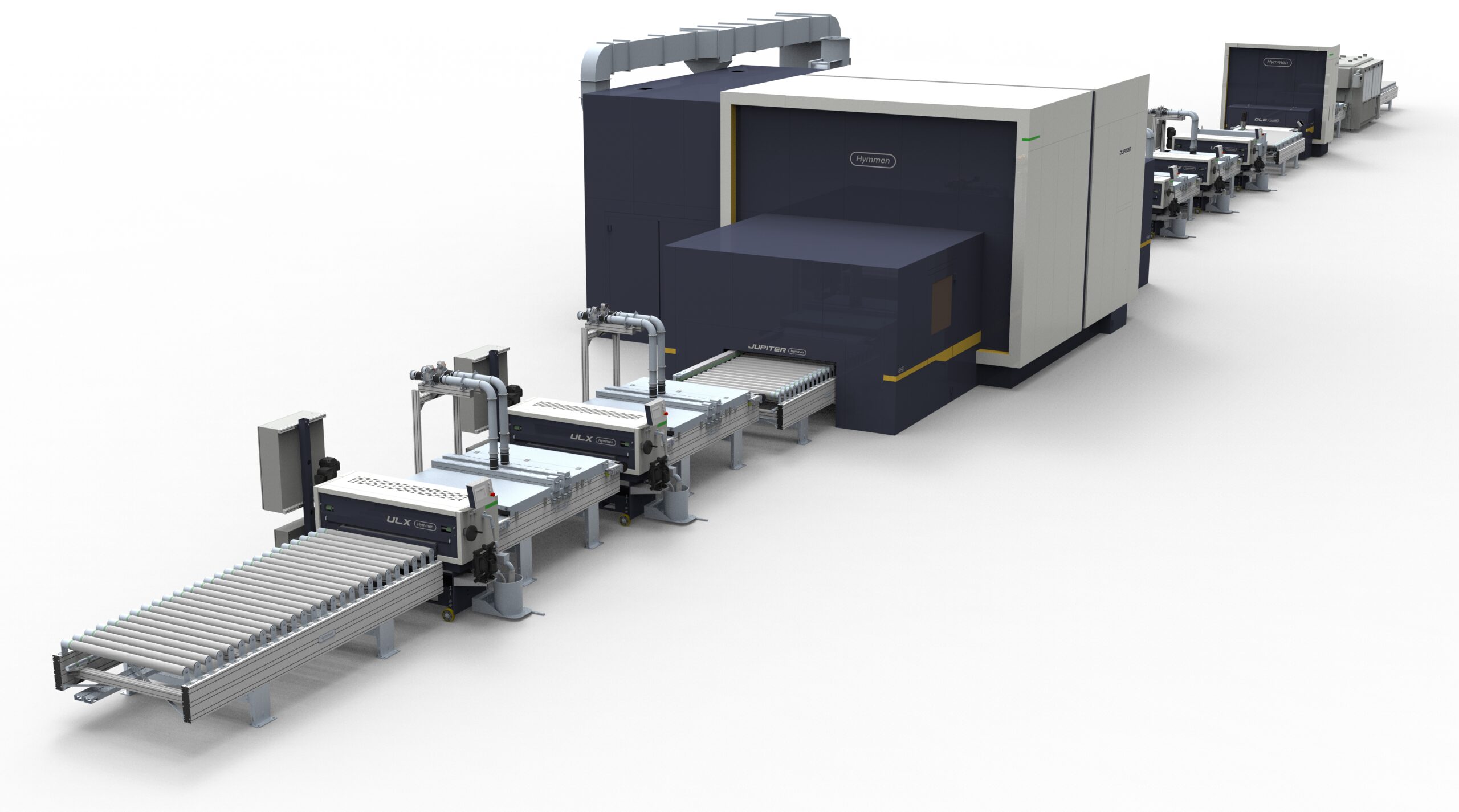

Presses

Double belt pressing lines, used in various global sectors, are known for their environmentally friendly and flexible continuous presses. Additionally, the multi-opening presses are ideal for efficient large-batch production.

Product information

Technical Features:

Multi-Opening Press:

• Number of openings: 20

• Specific pressing power: max. 760 N/cm²

• Heating plate size: 3,000 x 2,200 mm

• Space between openings: 90 mm

• Pressing cycle duration: 20 minutes

• Coated substrate: MDF and chipboard panels

• Substrate thickness: 6 – 32 mm

Double Belt Press – HPL

• Working width: 700 – 2200 mm

• Pressing pressure: up to 70 bar

• Speed: 3-45 m/min

• Temperature: up to 220°C

• Printing zone length: 3000-4000 mm

• Laminate thickness: 0.15-1.2 mm

Double Belt Press – MFC

• Working width: 1000-2500 mm

• Pressing pressure: up to 30 bar

• Speed: 15-40 m/min

• Temperature: up to 220°C

• Printing zone length: 3000-4000 mm

• Substrate thickness: 4-30 mm

• Number of openings: 20

• Specific pressing power: max. 760 N/cm²

• Heating plate size: 3,000 x 2,200 mm

• Space between openings: 90 mm

• Pressing cycle duration: 20 minutes

• Coated substrate: MDF and chipboard panels

• Substrate thickness: 6 – 32 mm

Double Belt Press – HPL

• Working width: 700 – 2200 mm

• Pressing pressure: up to 70 bar

• Speed: 3-45 m/min

• Temperature: up to 220°C

• Printing zone length: 3000-4000 mm

• Laminate thickness: 0.15-1.2 mm

Double Belt Press – MFC

• Working width: 1000-2500 mm

• Pressing pressure: up to 30 bar

• Speed: 15-40 m/min

• Temperature: up to 220°C

• Printing zone length: 3000-4000 mm

• Substrate thickness: 4-30 mm

Application Areas:

Laminates, compact panels for interior construction, compact panels for furniture sector, laboratories and hospitals, compact panels for building facades, elastic floors, edge bands, melamine panels, and conveyor belts.

Origin:

Germany

Differentiators:

• Uniform pressure distribution across the entire press surface.

• Savings thanks to the combined guide system and heating plate system.

• Space-saving lines.

• Lines available for product thicknesses with minimal tolerances.

• Heating and cooling under pressure in a single press.

• Savings thanks to the combined guide system and heating plate system.

• Space-saving lines.

• Lines available for product thicknesses with minimal tolerances.

• Heating and cooling under pressure in a single press.

Minimum purchase quantity:

On request.

Business contact

Our dedicated team is ready to learn more about your business and identify the best product for your needs.